Introduction to Cold Rolled Sheets (CR Sheets)

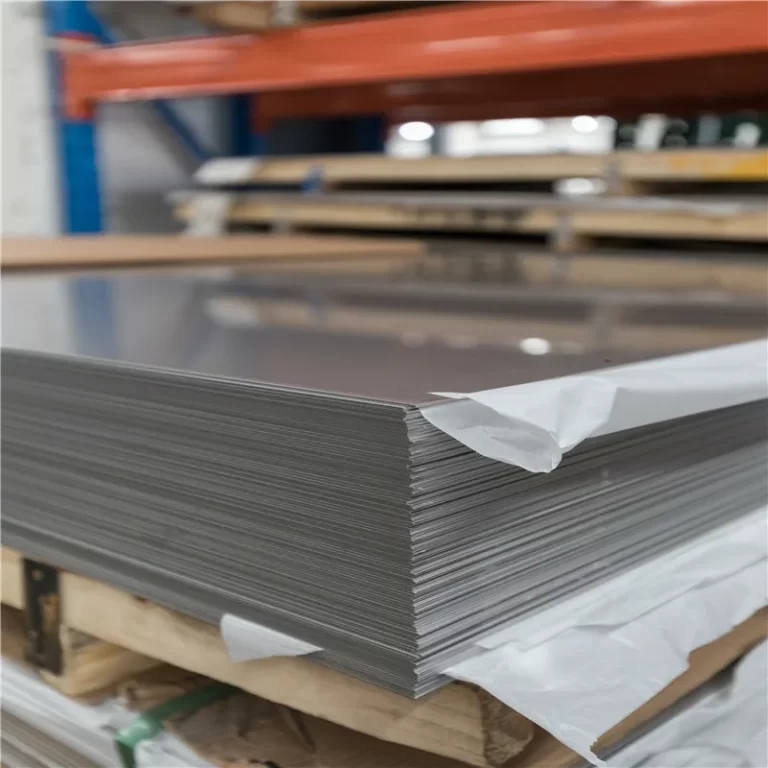

Cold Rolled Sheets, also known as CR Sheets, are an essential component of modern manufacturing, construction, and various industrial applications. Unlike hot-rolled steel, cold-rolled steel is processed at room temperature, which gives it superior surface quality, uniform thickness, and increased strength. This makes CR Sheets highly valued in industries such as automotive, appliance manufacturing, electronics, and construction.

At CAGHAN, we supply top-quality Cold Rolled Sheets sourced from our advanced manufacturing facilities in Turkey and Kosovo. With our base of operations in London, we ensure that all our CR Sheets meet the highest standards of durability, precision, and performance, providing UK businesses with reliable metal products for their industrial needs.

Cold Rolling Process – How CR Sheets Are Manufactured

The cold rolling process is a method of steel processing that reduces the thickness of steel while improving its mechanical properties. Unlike the hot rolling process, which occurs at elevated temperatures, cold rolling happens at room temperature. This process enhances the steel’s surface finish and mechanical strength, making it ideal for precise and demanding applications.

Cold Rolling Process Steps:

Initial Heating: Hot-rolled steel is first heated to a manageable temperature, but not to the high levels used in hot rolling.

Rolling: The steel is passed through a series of rollers, which progressively reduce the thickness.

Annealing: After rolling, the steel may undergo an annealing process to relieve internal stresses and enhance the material’s ductility.

Pickling: The steel may also be pickled to remove any oxide layers or rust, ensuring a clean surface.

Finishing: The final sheet is cut to the desired width and length, and any surface imperfections are smoothed to achieve a high-quality finish.

This cold-rolling method results in a product with improved surface quality, dimensional precision, and stronger mechanical properties compared to hot-rolled steel. The sheets are then used in a wide array of applications, ensuring both durability and aesthetic appeal.

Specifications of Cold Rolled Sheets (CR Sheets)

Cold Rolled Sheets are available in various thicknesses, grades, and finishes. The specifications of CR Sheets vary depending on their intended application, and it’s important to choose the right grade and thickness for your project.

| Specification | Details |

|---|---|

| Thickness | 0.3mm – 4.0mm |

| Width | 600mm – 1500mm |

| Length | 2000mm – 6000mm (Custom lengths available) |

| Grades | DX51D, SPCC, SPCD (Custom grades available upon request) |

| Surface Finish | Bright, Smooth, Clean |

| Tensile Strength | 300 MPa – 550 MPa |

| Yield Strength | 250 MPa – 450 MPa |

| Hardness | 50 HRB – 80 HRB |

| Surface Treatment | Galvanized, Pre-painted, or uncoated |

These specifications ensure that CR Sheets provide superior performance in a wide range of industries, where precision and strength are required.

Advantages of Cold Rolled Sheets

Cold Rolled Sheets are widely used due to their numerous advantages over other types of steel sheets, particularly hot-rolled steel. Some of the primary benefits of CR Sheets include:

Superior Surface Finish: Cold Rolled Sheets have a smoother, more refined surface compared to hot-rolled steel, making them ideal for applications where surface quality is critical. This makes them perfect for products requiring painting, coating, or other surface treatments.

Enhanced Strength and Durability: The cold rolling process improves the strength of the steel, giving it higher tensile strength and yield strength. This results in a more durable and long-lasting material, ideal for structural and load-bearing applications.

Dimensional Precision: The cold rolling process provides a high degree of accuracy in terms of sheet thickness and overall dimensions. This is crucial for industries where precise measurements are essential.

Increased Formability: Despite the higher strength, Cold Rolled Sheets are more ductile and easier to form than hot-rolled sheets. This makes them ideal for applications where complex shapes and designs are required.

Corrosion Resistance: Cold Rolled Steel is more resistant to rust and corrosion compared to hot-rolled steel, making it a preferred choice for outdoor and exposed applications.

Versatility: CR Sheets are versatile and can be used in a variety of applications, ranging from automotive parts to household appliances, construction materials, and more.

Common Applications of Cold Rolled Sheets (CR Sheets)

Cold Rolled Sheets are used in numerous industries due to their versatility, strength, and smooth surface finish. Some of the most common applications of CR Sheets include:

Automotive Industry: CR Sheets are extensively used for the production of automotive body panels, chassis, structural components, and trim parts. The high strength and formability make them ideal for automotive manufacturing.

Construction: Cold Rolled Sheets are commonly used in construction for making structural elements like walls, ceilings, and roofing. The sheets can also be used for making decorative panels, cladding, and HVAC systems.

Appliance Manufacturing: CR Sheets are widely used in the production of home appliances such as refrigerators, washing machines, microwaves, and ovens. Their smooth surface makes them suitable for painting and coating, ensuring an aesthetically pleasing finish.

Electronics and Electrical Products: In the electronics industry, CR Sheets are used for making parts for computers, mobile devices, electrical enclosures, and other high-tech components where precision and surface finish are important.

Furniture: CR Sheets are used in furniture manufacturing, particularly for making steel frames, office furniture, and storage systems. Their strength and durability are essential for the longevity of the products.

Why Choose CAGHAN for Cold Rolled Sheets?

At CAGHAN, we pride ourselves on offering high-quality Cold Rolled Sheets that meet the specific needs of our customers. Our products are sourced from our advanced manufacturing facilities in Turkey and Kosovo, and we deliver them directly to businesses in London and across the UK.

We understand the importance of precision, durability, and quality in your projects. Whether you’re working on an automotive project, constructing a building, or manufacturing household appliances, CAGHAN provides the cold rolled sheets that meet your exact specifications.

Conclusion

Cold Rolled Sheets (CR Sheets) are one of the most versatile and valuable materials in the manufacturing and construction industries. Offering superior surface finish, enhanced strength, and high precision, these sheets are crucial for applications that require durability and a refined appearance.

At CAGHAN, we are committed to providing top-quality Cold Rolled Sheets that meet international standards for strength, precision, and surface finish. Our CR Sheets are available in a wide range of grades, thicknesses, and finishes to suit your specific needs.

For more information or to place an order, contact us at sales@caghan.co.uk. Our team is ready to assist you with your next project.

About Us

CAGHAN is a leading supplier of high-quality metal products based in London, UK.

At CAGHAN, we take pride in delivering superior materials, including Cold Rolled Sheets, Galvanized Sheets, Pipes & Tubes, and other metal products that cater to the unique needs of each of our customers.

- Why Choose CAGHAN?

- Superior Quality Materials

- Global Manufacturing Facilities

- Precise Engineering

- Expert Technical Support

- Timely Delivery and Reliability

- Competitive Pricing

- Environmental Responsibility

- Customer-Centric Approach

What types of metal products does CAGHAN supply?

We provide a wide range of high-quality metal products, including Cold Rolled Sheets, Galvanized Sheets, Pipes & Tubes, Structural Profiles, and Construction Profiles. Our products are suitable for industries such as automotive, construction, electronics, and more.

To receive a personalized quote, simply contact us at sales@caghan.co.uk with your project details or use the form on our website. Our team will provide you with a competitive price and delivery options tailored to your needs.